Coatings In Disguise

Powder Coatings are usually seen in solid color or metallic shades, decorating metal parts (and sometimes wood, glass or plastic).

They provide a tough, anti-corrosive finish that protects and decorates the product.

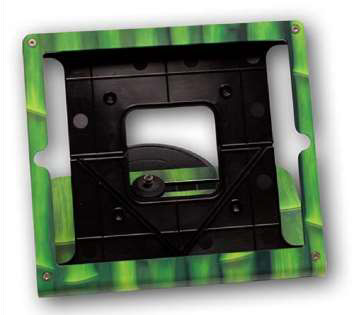

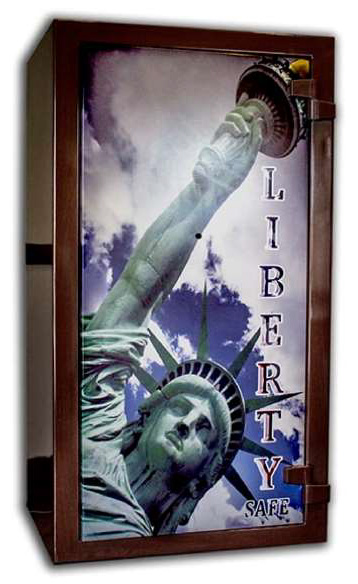

Sometimes that coating is decorated in such a way that the surface of the substrate appears to be disguised as another material – making metal look like wood, or aluminum look like stainless steel… We call these Decorative Powder finishes.

Decorative Powder Finishes

There is only one truly affordable method for disguising substrates to have the appearance of other materials using the powder coating process, this is a Patent Pending sublimation method more commonly known to us here at Pixel as our EmBlazing process.

Some of the more common uses of sublimation technologies today are to make aluminum windows and doors appear like wood, on children’s furniture, surfboards, retail signs and more.

Selling prices can be 250-400% higher than for standard powder finishes, so selling products with Decoration can lead to a higher margin business.

Durable Digital Printing

Durable Digital Printing

Providing the same dirability as conventional polyester powder coating, The digital printing process becomes integrated into the powder coating finish and receives all the characteristics of the original powder coat as well as the finish.

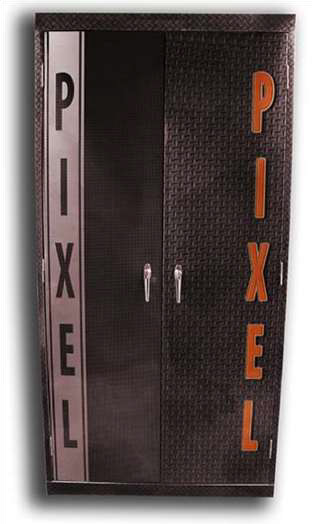

The Pixel process can decorate many interior projects by “printing” precise patterns, images or pictures. Photographs and graphics can be utilised, along with images of marble, stone, plaster, textures …and of course wood. The process is compatible with aluminum and steel substrates. The process embedds the image into the powder coating. The process normally comprises 3 steps:

- First Pretreatment of product

- Second powder coating the product with dye receivable powder

- Third applying media and placing in an oven allowing for the transfer of dyes into substrate.

Emblazing Process

Pixel was the first company to develop a system and a product for sublimation that could be done without the use of expensive equipment and or vacuum bags. All that is needed is the Pixel media and an oven.

The Pixel Benefit

Environmentally Friendly

No Solvent emissions on conventional and multi-faceted pieces

Design flexibility - Provides excellent edge coverage

Consistent quality across and between the different parts

Media And Equipment

Media And Equipment

We can connect you with suitable licensed Pixel partners for transferring the printed media images to your powder coated products. Contact Pixel directly and get started today!

Media is available in hundreds of patterns. Buying an existing library pattern is less expensive than having a new pattern made but because the process is digital you can have your patterns created by us for a small fee. Prices are calculated per square foot and will vary depending on the type and quantity of the media that you choose.

Sublimation Technology

Previously, the use of dye-sub printing was limited to industrial or high-end commercial printing. Dyesub photo printing has been used in medical imaging, graphic arts proofing, security, textiles, and broadcast related applications. Now through Pixel it is available for the powder coating industry.

Sublimation Uses

The sublimation printing process is used to print on polyesters, synthetic coatings, and fabrics. it has been used for various applications such as T-shirts, banners, table covers, id cards, handrailings, sportswear and flags. The dye sublimation inks are a pigment suspended in a liquid solvent, like water.

Advantages Of Sublimation

- Images are permanent and are protected by the substrates characteristics and properties which do not change as a result of the sublimation process and do not peel.

- Dye does not build up on substrate

- Colors can be extremely vibrant and life like.

- Photographic quality can be achieved replicating almost anything that can be imaged.

- The image is embedded into the substrate.

- The image is protected by the substrate.

- Products that have been imaged have a much higher perceived value and can drive higher margins with less effort for the ROI.

- The images are initially created on transfer media as a reverse image of the final design, which is then transferred onto polyester or synthetic materials that have been placed in a Oven operating at a temperature around 180° to 220° C (400° F).

- Under high temperature, the dye turns into a gas and permeates the substrate and then solidifies into its fibers.

- The substrate is permanently dyed so it can be cleaned or washed without damaging the print quality or removing the image from the substrate.

Pixel

has worked with manufacturers to develop specialty powders that compliment the new process by Pixel. The powder coating for the Pixel process needs to be specially formulated.

Key elements are to ensure:

Proper ink transfer.

Correct color. Ensuring color match

Repeatability in the production process.

No Equipment

Pixel has developed a Patent Pending method of sublimation that does not require special equipment. This method eliminates cost as a barrier of entry for sublimation into powder coating.

Contact us here at Pixel so you can evaluate the potential of the process for your products.

>>> Continue on to the Emblazing Image Gallery <<<

Pixel is committed to turning your Vision into Reality!

Quality Assured

Pixel stands behind its work and guarantees quality and consistency.

![]()